We hold the dominant share of the global market for PFA roto molded tank.

Rotomolded (rotational molded) is one of technology for forming container. It’s characterised by a special weldless smoothness design, molded as one body and greatly enhanced the durability of the tank. It can be used safely for transport and storage of dangerous chemicals by using fluororesin PFA with excellent features such as chemical resistance and non-adhesiveness to raw materials. We have an overwhlmingly large share of PFA roto molded tank in Japan and overseas. It is designed to be flexible different nozzle are positioned and various tank shapes specific application and also shapes of nozzle the highest point. Integrated clevis tank is finalized by using PTFE of fluororesins same as the PFA to nozle and clevis machining after welding. This technology is our original and products type of installing exterior materials such as SUS, PVC, FRP as capacity to resist pressure container. for a chemical supply. It has strength can withstand N2 under pressure for a chemical supply and it’s really useful at semiconductor and LCDs facilities tank.

ETFE lining sets to revolutionise tanker

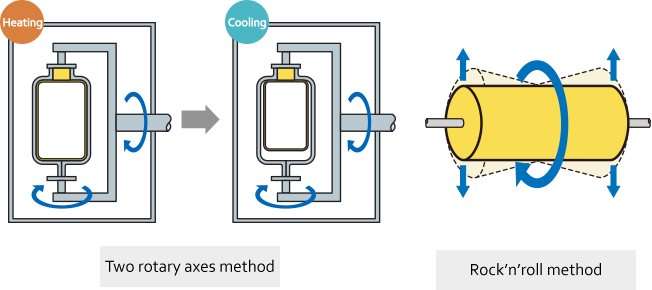

Rotomolded (Rotational molded) has several types and above PFA rotomolded tank uses in two rotary axes which the combination of rotation and revolution Besides, a molding method called rock and roll which the combination of rotation and swinging This technology makes use lining for coating ETFE to huge inside tank lorries. It’s characterised by a special weldless smoothness design, in superior adherence to ETFE and greatly enhances the durability of the tank. Moreover, simplify cleaning and its possible to share and transport chemical liquid. It is mainly used for tanker that transport waste fluid and waste acids, etc. from the factory, known as the super flow lining. We have provided since 1996 and production of more than 600 tanks. It’s one of the major product lines.

We take a flexible approach based on higher customers' needs and always leads the industry.

We started to product of fluororesin tank by rotomolded (Rotational molded) from 1993. Initially available only the small tanks themselves but we expand variations of capacity, shape and exterior for increasingly complex needs. We have earned Numerous customers' trust. We are expected to need for more larger, a long lifetime and high purity due to the evolution of technologies. We think that the mission of the company pushing forward with research and development to keep ahead of the competition in the field to with the highest demands.

Yodogawa Hu-Tech Co., Ltd

Shiga Factory Section chief of Technology Department

Yodogawa Hu-Tech Co., Ltd

Shiga Factory Section chief of Technology Departmentand the Chief of Manufacturing Division

The Department of technological development the technical management

Deguchi Yujirou

There are not many opportunities to see after shipment because the tank is used as manufacturing equipment. I am proud that our work is to support the development of Japanese industries even out of sight. Production of fluororesins tank by rotomoleded (rotational molded) is one of the core technology. My goal is to raise the level it and produce more products. We brainstorm ideas raising awareness, having a wide field of vision and gathering information within and outside the company.