The World's No.1 Share for Large-sized LCD Manufacturing Line

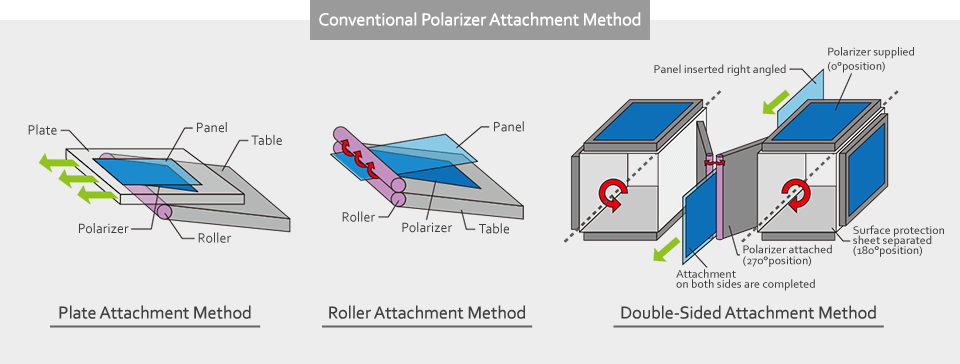

Manufacturing LCD requires attaching polarizer on both surfaces of the panel. Yodogawa Hu-tech has been manufacturing automatic polarizer attachment equipments since 1985. In the beginning, running panel and polarizer between two rollers was the method. To make the attachment process more precise, in 1990’s suctioning plates during the process became mainstream. In 2000’s, TV screens got larger, which at the same time, made efficiency and space-saving design an urgent matter. We’ve developed a method to insert panel right angled so it can simultaneously attach polarizer from both right and left side. Then in 2007, launched an equipment which inserts, peels the separator (surface protection seal of the polarizer), and attaches the polarizer by rotating the processing table. This increased manufacturing speed rapidly. Yodogawa Hu-tech now holds a world wide share of 70% for large LCD manufacturing line.

Solved Diverging and Warping problem with Epoch-making Invention

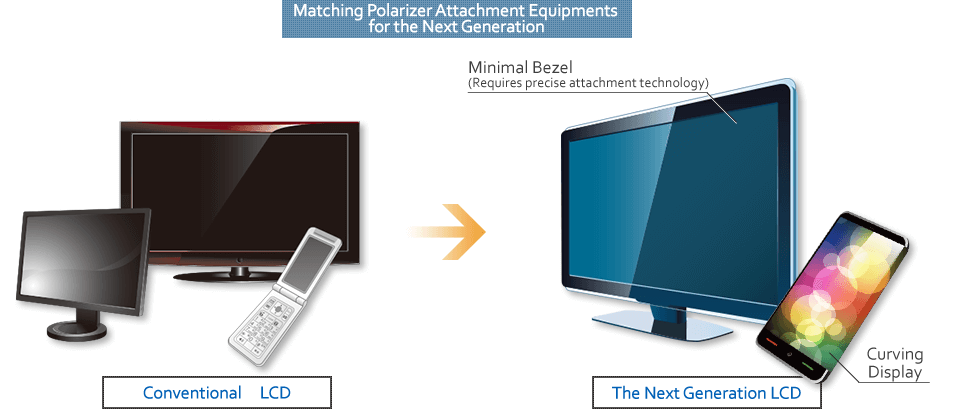

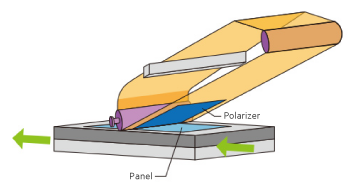

As smart phone and tablet spreads, it became more important to make screens wider as possible. Televisions with minimal bezel are the mainstream nowadays, and allowable range of attachment error is requested to be within ±0.05mm. However, with former method running between two rollers made slight diverge and or warp occasionally. To solve this problem, we developed a system to attach polarizer even more precisely in 2012. Polarizer adhered to the sheet rotating around two rollers, and attaching onto panel conveyed right below. No warping occurs compared to the former method that needs to stretch the polarizer while attachment.

Entering New Business fields such as OLED and Expanding Market Share

High precision polarizer attachment equipments for small-sized LCDs are already in the manufacturing line in Japan and overseas. Demo-units for larger-sized LCDs already passed our customers’ requirements and expected to be adopted to their plants in 2017. With the technology producing irregular and curved shaped LCDs, we’re starting to expand the share for smart glasses and smart watches. We will be continuously working to match every customers’ requests, and plan to break new ground in OLED expanding our market share.

Yodogawa Medec Co.,Ltd

Operations Promotion Group

Yodogawa Medec Co.,Ltd

Operations Promotion GroupManufacturing Organization Group Section Chief

Kouji Yamashita

“Could you do it?” Our development starts when we receive a request from a customer, and we are the company who achieves a solution to it. We never reply “We Can’t” to the customers with expectations for us. I rather feel highly grateful for the chance given to improve our technology. Originally we, Yodogawa Medec, have been developing equipment pasting photos to postcards, and connecting films before they are developed. Pasting or “attaching” technology is what we have investigated for many many years, so we’re confident that we can live up to any demands. Our group’s philosophy is “Something New.” Exactly as is, we’ll continue to produce the novelty, and it surly will make your business a lot better.