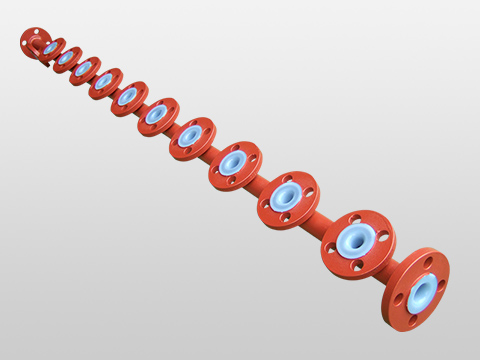

Loose lining

It’s possinble to mold that "tube-type loose lining" which inserting ETFE and PFA resin's tubing into metal pipes and flare processing both ends and wetted parts coated with fluororesin and "Transfer molding" that inserting a metal corrugating medium into outer tube and melting and lining resin to put it between outer tube and corrugating mededium in furnace.

All cases lining construction method that outer tube and resin's film wouldn't adhere is referred to as a “loose lining".

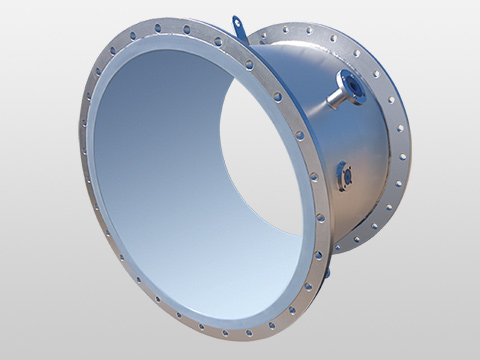

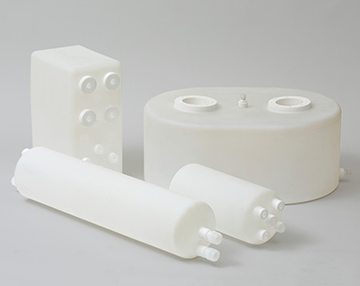

Rotational molding lining

It’s lining molten resin into metal substrate through centrifugal force that it put resin raw material into metal substrate and keep in closed pipes and tank, etc. and set into furnace and also be rotated and heat vertical, horizontal and both axes at a same time. We can flexibly respond to set various special shapes by this method.

Furthermore, its possible to use under negative pressure because of linings attached to base metals.